Didactic milling machines

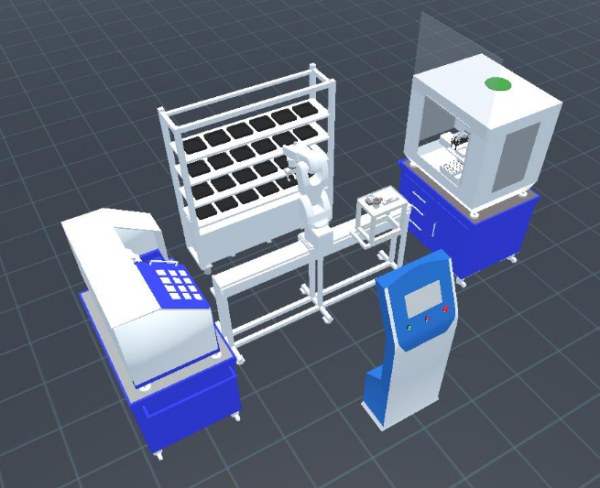

TiCOR educational station

342 300,00 zł net

No rating

12 months of warranty

Contact with a trader:

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

CNC machining center, cnc lathe with 6-axis robot with pneumatic chuck.

Quantity

Add to cart

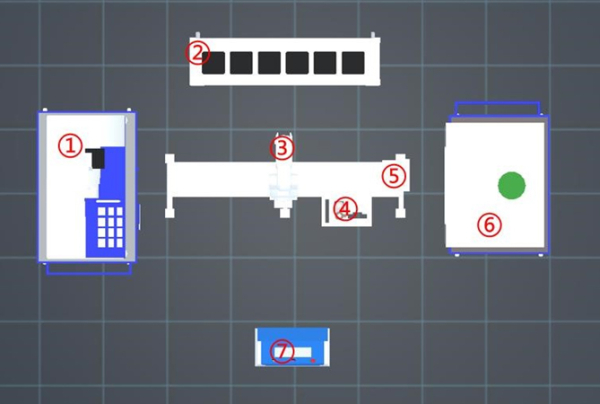

①SKOLAR i4S CNC lathe with pneumatic door, pneumatic chuck and I/O communication port.

② 3D library of 20 workstations, including workpiece positioning devices and library location detection signals.

③ 6-axis robot with pneumatic chuck. (Recommended brand Effort)

④ Robot chuck library, including 2 sets of quick-change chucks.

⑤ 7th-axis robot with a stroke of 1.5 meters. The base of the 7th axis is an aluminum alloy frame with 4 wheels at the bottom. The robot control cabinet and air compressor are placed at the bottom, including the air compressor components.

⑥ SKOLAR iX1 CNC machining center with pneumatic door, single-axis pneumatic vice and I/O communication port.

⑦ System control cabinet including 9-inch HMI human-machine interaction interface, 1200 PLC, network switch and control circuit.

Knowledge and skills that can be achieved:

The TiCOR machine tool loading and unloading workstation has movable wheels at the bottom of the machine tool module, three-dimensional library module and robot module. The I/O communication port between CNC machine tools and robot is installed outside the CNC machine tool housing, which enables the workstation to be separated and connected quickly and conveniently. The CNC lathe, CNC milling machine, three-dimensional library, robot, etc. communicate with the system control cabinet through I/O and network interfaces. The operation logic of the TiCOR workstation is programmed by PLC. Through the HMI human-machine interaction surface, each individual device can work and operate as a whole.

- TiCOR workstation enables independent training and operation of CNC machine and robot, as well as CNC machine processing programming and robot control programming.

- It can realize automatic loading and unloading functions and workstation programming training.

- It enables learning various knowledge related to the comprehensive loading and unloading of lathes and milling machines, such as understanding the claw library, replacing the original claw, claw design, etc.

- It enables learning knowledge about communication and information exchange between CNC machine and robot.

- It can realize training of various production processes on TiCOR workstation.

- Loading, processing and storage on lathes,

- Milling machine feeding, processing and storage,

- Milling machine feeding, processing and storage,

- Milling machine feeding, processing, lathe processing, storage

- It can realize PLC and HMI programming education and training.

* Illustrative photo of the machine, in reality it may differ in details or parameters.

Recommended

Didactic milling machines

560 142,00 zł

No rating

Didactic milling machines

94 710,00 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.